Products Category

Contact Us

Name: SANDY ZHANG (Mr.)

Tel: 0086 21 2024 7525

Fax: 0086 21 6839 2881

E-mail: help@minkvon.com

Add: ROOM 15-A-A291, NO.1-42, LANE 83, HONGXIANGBEI RD., WANXIANG TOWN, PUDONG NEW AREA, SHANGHAI, CHINA

Commercial Hair Straightener and Hair Curlers for Hairdressing Industry

Description of project

The solution design in this project is based on “new type heating material” combined with “classical display-control unit ”.

The design increased heating rate of the heating part of hair straightener / curler product based on reliable temperature control for overheat protection issue.

|

Project â„–

|

MKMK1111032056

|

|

Application Origin

|

South-east Asia, Europe

|

|

Project Cycle

|

35 working days

|

|

Mass Production Date

|

2011-12-22

|

Technical design

|

Working Voltage

|

220~230 V AC

|

|

Rated Power

|

600~800 W

|

|

Heating Feature

|

Rapid warming, Constant power

|

|

Way of Thermal Transfer

|

Thermal Conduction

|

|

Security / QC Standard

|

CE, RoHS

|

|

Device Part â„–

|

MCH120/14/6/150/230-220

|

Design of Heating Unit

|

Heating Material

|

Ceramic Heating Element

|

|

Thermal Transfer Material

|

Aluminum Alloy Plate

|

|

Insulation Material

|

Polyimide Insulation Film

|

Matching Parts and Auxiliary Equipment

|

Power Supply Unit

|

2 PIN Power Cord, 2*0.75 mm²

|

|

Control / Displaying Unit

|

PCBA, LCD / LED

|

|

Overheat Protection Unit

|

Restorable thermostat

|

|

Mounting Unit

|

Plastic house

|

|

Thermal Transfer Auxiliary Unit

|

No

|

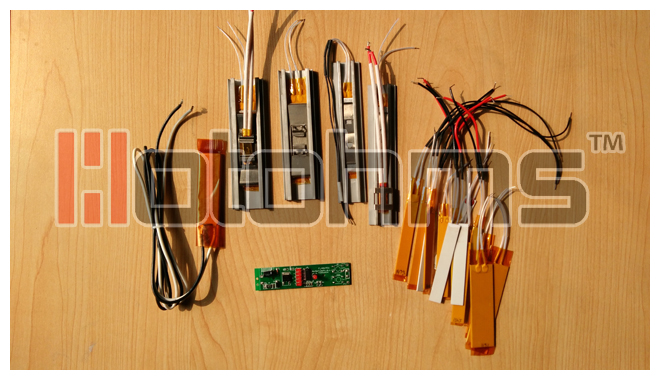

Previewing on some of the final products:

Project Tracking and Improvement

Heating Element Device

Heating Element Device PTC Series

PTC Series